Non-Destructive Test

🎯 Definition of Non-Destructive Testing

Non-Destructive Testing is a technology that inspects · determines the incompleteness of the object to be inspected without damaging the object to be inspected using the principle of physical phenomena, and inspects the internal structure of the part and the accept · reject of defects.

🎯 Method of Non-Destructive Testing

- Radiographic

Testing(RT) - Ultrasonic

Testing(UT) - Magnetic Particle

Testing(MT) - Penetrant

Testing(PT) - Eddy Current

Testing(ECT) - Leak Testing

(LT) - Visual Testing

(VT)

Eddy Current Testing

Principle and Method

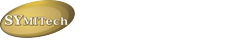

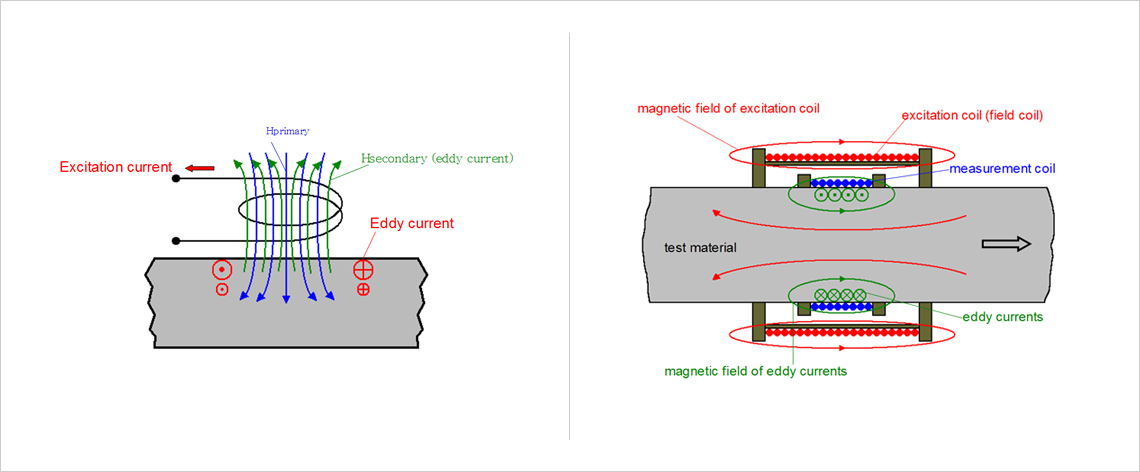

When a coil of alternating current approaches a conductor such as a metal, an eddy current(also referred to as an induced current) is induced inside the conductor due to the magnetic field generated around the coil.

The eddy current is changed when there is a discontinuity such as a crack in the conductor, and the defect is detected by using the change of the eddy current.

It is mainly used in the inspection of the heat exchanger tubule, and has the excellent sensitivity to detection of surface defects and preservation of records.

Scope

- Steel pipe surface inspection

- Bar steel surface inspection

- Rolling roll inspection

- Wire inspection

- Inspection of automobile parts

- Inspection of aerospace parts